Iron Ore Mining Process Flow Chart India

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 — Iron Ore production in the Pilbara Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following 2017年11月17日 — Indian iron ore mine have been operated by selective mining to maintain the high grade iron ore (Fe>60%) , however, it is extremely difficult to practice the same Iron Ore Processing eprintsnmlindia2022年5月4日 — the most important iron ores in India About 79% haematite ore deposits are found in the Eastern Sector (Assam, Bihar, Chhattisgarh, Jharkhand, Odisha Uttar IRON ORE Indian Minerals Yearbook 2019 IBM2016年1月28日 — India is endowed with significant iron ore reserves, estimated at 2525 Billion tonne apart from Banded HaematiteQuartzite (BHQ) and Banded Haematite Advances in Low Grade Iron Ore Beneficiation MECON

Simplified flow chart showing typical iron ore

2024年7月1日 — The aim is to establish correlations between basic iron ore tailings data and CS parameters, providing a screening approach to determine whether laboratory results fall within expected rangesTypical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you Iron Ore Processing Flowsheet Multotec2017年8月28日 — A Case Study: Iron Ore Mining in India Abstract In this chapter a case study from Jharkhand state in India is presented to demonstrate the quantitative Chapter 8 A Case Study: Iron Ore Mining in India Springer2024年8月17日 — The steel sector relies on the availability of resources like iron ore, coking/metallurgical coal, steel scrap and power India has adequate iron ore reserves, Steel Coal and Iron ore report EY

.jpg)

IBM Indian Bureau of Mines

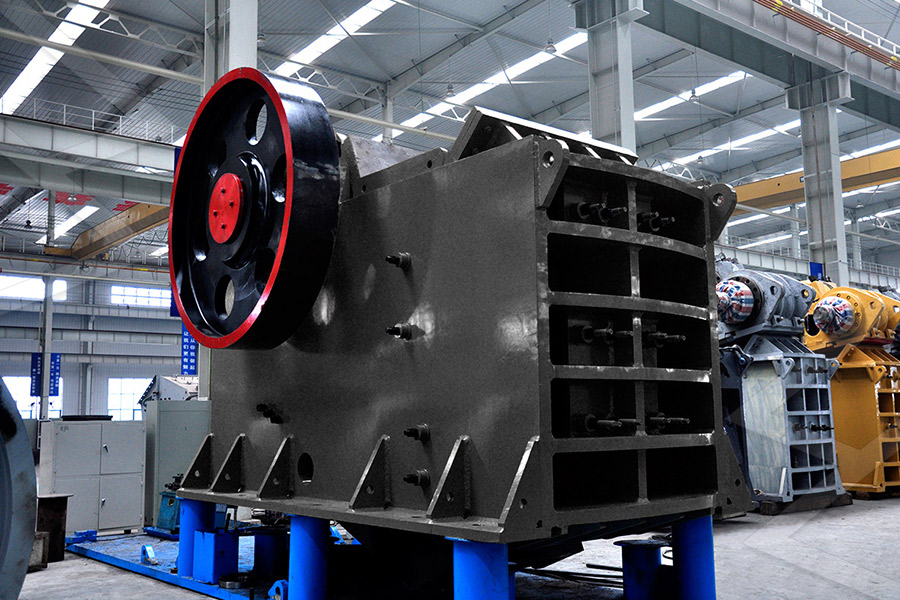

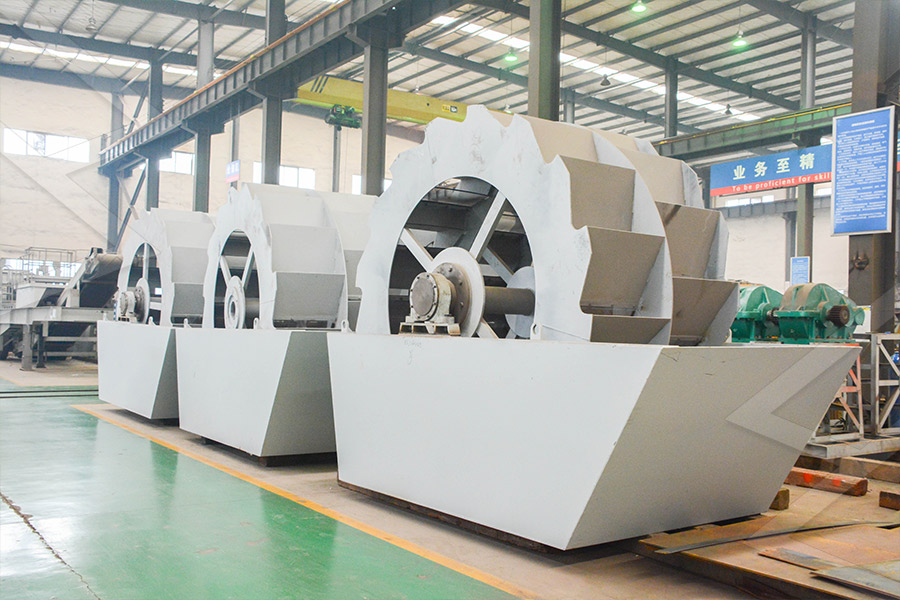

2017年6月15日 — IBM Indian Bureau of MinesIron ore processing refers to the techniques used to extract iron from oolitic iron ores, involving processes such as beneficiation, roasting, and magnetic separation to remove Iron Ore Processing an overview ScienceDirect Topics2018年7月11日 — The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and low Iron Ore Pelletizing Process: An OverviewIOC's production process begins in the mine with drilling and blasting The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pit "We are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations Our Mining Process Iron Ore Company of Canada

IRON ORE Indian Minerals Yearbook 2019 IBM

2022年5月4日 — from Private Sector Among 35 iron ore mines in Public Sector, 18 iron ore mines each producing more than one million tonnes annually accounted for about 9606% of the total output in Public Sector during 201819 Out of 219 iron ore mines and 8 associated mines in Private Sector, 30 iron ore mines each producing more than2020年2月8日 — The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making With the highgrade ores depleting very fast, the focus is on the beneficiation of lowgrade resources However, most of these ores do not respond well to the conventional Existing and New Processes for Beneficiation of Indian Iron 2023年1月1日 — The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and Iron ore beneficiation: an overview ScienceDirect2023年12月19日 — Using a process that combines coking coal with reduced iron pellets, steelmaking has become one of the world's most vital industries Everything in iron ore mining is big Countries like India are expected to rise, somewhat offsetting the lack of demand from traditional ore buyers worldwideIron Ore Mining Process: From Extraction to Export

Iron Ore Processing, General SpringerLink

2022年10月20日 — Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions It is the link between the mined raw In Goa Foundation vs Union of India Ors, the NGT suspended the ECs granted by the MoEFCC to 72 iron ore mining projects in Goa for violating the EIA Notification, 2006 and the Forest (Conservation) Act, 1980Environmental Clearance Process for Mining Projects in India2017年11月17日 — iron ore reserves [1] P rocessing of low grade iron ore is inevitable as a r esult of increase in production and consumption of high grade ores Though Indian iron ore is rich in iron but it contains high alumina, which is not favorable for efficient operation of blast furnace [2] Indian iron ore mine have been operatedIron Ore Processing eprintsnmlindia2 天之前 — Pyrite mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more Gold Diamond Mining Process in Angola 50TPH Alluvial Diamond Mining Process in Central African 50TPH Diamond Extraction Process Flow Chart 60TPH 15TPH Tailings Lead Barite Pyrite Mining Processing Equipment Flow Chart Cases

.jpg)

Iron Ore Supply Chain: From Mining to Steel Production

2023年10月25日 — Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities The iron ore supply chain begins with the mining of iron ore, which is then transported to processing plants for beneficiation and further refinement The refined iron ore is then transported to 2024年3月5日 — Iron Ore Iron ores are rocks and minerals from which metallic iron can be extracted; India has large iron ore reserves It occurs in various geological formations but major economic deposits are found in Mineral Resources: Iron Ore distribution in India2023年6月20日 — Iron ore mining in India has a rich history that spans thousands of years, shaping the nation's economy and contributing significantly to the global iron ore trade This article aims to provide a comprehensive analysis of India's iron ore industry by examining its historical development and exploring the contemporary trade dynamicsIron Ore Mining in India: A Historical Perspective and2023年2月15日 — Mediumgrained hematite refers to iron ore with an embedded particle size between 002 and 2mm This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting Finegrained hematite refers to iron ore with an embedded particle size of less than 002mm Based on the genesis of How to Extract Iron from Hematite: Methods and Plants

Iron Ore an overview ScienceDirect Topics

Latest Developments in the Iron and Steel Industry Dilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 222 Milestones Iron ore has been smelted in crude furnaces in the Indian subcontinent for at least the last 3000 years, but the history of its modern iron and steel industry is short The arrival of a fully integrated steel mill on 2015年7月14日 — This gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by ball mill After the ore fine grinding ball mill into the next process stepGold Mining And Processing Flow Chart2024年4月25日 — MINING MINERAL STATISTICS DIVISION CCoM (MES) Pankaj Kulshreshtha "Indian Mineral Industry at a Glance 202021" is the 40th edition in its series This is a combined issue composing updated data for 201819, 201920 202021 to Iron Ore (Haematite) 1000 Tonnes Indian Mineral Industry at a Glance IBM2015年4月3日 — Understanding Iron Ores and Mining of Iron Ore satyendra; April 3, 2015; 0 Comments ; blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining,; Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on Understanding Iron Ores and Mining of Iron Ore – IspatGuru

Ironmaking 101 – From Ore to Iron with Smelting and Direct Iron

2017年10月17日 — Smelting Reduction Figure 2: The smelt reduction vessel (SRV) is the core technology component of the Hismelt process Source: RioTinto While years of ironmaking technology innovations have optimized blast furnace productivity, two alternative processes—smelting reduction and direct iron reduction— are growing in adoption The 2024年3月20日 — The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram It discusses the key ingredients involved in steel production, their roles, advantages and disadvantages of the Understanding the Steel Making Process: A Flow Diagram2018年9月17日 — 3 Introduction Iron is the fourth most abundant mineral on earth having a reserve of 170 billion tonnes of crude iron ore Iron steel is the driving force behind industrial development in any country The Seminar on iron ore beneficiation in india PPTTypical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you Iron Ore Processing Flowsheet Multotec

Introduction: Overview of the global iron ore industry

2022年1月1日 — Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore KIOCL Limited (Formerly known as Kudremukh Iron Ore Company Limited), a Flagship Company under the Ministry of Steel, Govt of India was formed on 2 April 1976 for mining and beneficiation of low grade iron ore at Kudremukh, Karnataka, IndiaKIOCL has been a pioneer with over four decades of experience in operating Iron Ore Mining, Beneficiation KIOCL LtdSeveral dam failures of residues from iron ore mining happened in this area, including the Mariana dam disaster in 2015 and the Brumadinho dam disaster in 2019 China, India, Russia and South Africa All raw materials are ultimately confined to these locations of supply Impact Rating Type Tailings are the waste materials that remain Environmental Impacts of Iron Ore Mining UKGBC2016年8月24日 — This special issue of Mineral Processing and Extractive Metallurgy presents a selection of the best metallurgy papers delivered at the very successful international ‘Iron Ore 2015’ conference held at the Perth Convention and Exhibition Centre, Australia, on 10–12 July 2015 This was the seventh in the series of biennial conferences Full article: Iron ore processing Taylor Francis Online

.jpg)

(PDF) Iron Ore Tailings: Characterization and Applications

2021年1月1日 — Stages of the iron ore bene ciation process, using otation methodology the weight of the total iron ore mining 13,18 12 Generation iron or e tailings 180 million tons and is Businesses Home > Our Businesses overview > Manufacturing > Iron Ore – Beneficiation Pelletization Division > Iron Ore Beneficiation Pelletization (IoBP) Overview Products Technology Location Overview Essel Mining and Industries Limited (EMIL) is a pioneer in manufacturing of iron pellets through the distinguished and most compact circular Our Businesses overview > Manufacturing" h="ID=SERP,52962">Iron Ore – Beneficiation Pelletization Division EMIL Essel Mining2013年1月1日 — The process of developing an iron ore mine from exploration data through to informed mining decisions provides an ex ample of a Complex Ada ptive System The detailed composition of an Planning an Iron Ore Mine: From Exploration Data to Informed Mining 1 天前 — The actual mining of gold is just one step of the gold mining process Learn how gold is mined and the five stages of a large scale gold mining project Skip to main content Global Global 中国 as accurately as possible, the size of the mineral deposit, as well as how to extract and process the ore efficiently, safely and responsibly It How Gold Is Mined Gold Mining Process World Gold Council

SPECIAL IRON ORE PROCESSING ISSUE Development of

2018年10月22日 — 20 Mt/a iron ore fines The fast depletion of highgrade iron ore fines, increased industrial demand and an increase in iron ore prices have necessitated the exploitation and use of lowgrade iron ore fines in the steelmaking process after beneficiation Thus, the beneficiation of lowgrade iron ores by removing theIron ore beneficiation has lagged in India because of challenges such as the area required for tailings and transportation costs, statecontrolled mining firm NMDC technical director Vinay Kumar said Tailings refer to the waste generated by the beneficiation process Constructing more slurry pipelines would reduce logistics expenses, Kumar addedIron ore beneficiation key for India’s steelmaking goal2023年10月2日 — In the dynamic world of mining, Derrick Corporation has become synonymous with innovation W ith a legacy rooted in Australian iron ore processing since the 1950s, Derrick Corporation continues to Revolutionising iron ore processing Australian 2024年6月18日 — The Joda East Mine, owned by Tata Steel, is a surface mine located in Odisha The mine produced an estimated 1004 mtpa of iron ore in 2023 Buy the profile here 5 Noamundi Iron Ore Mine Owned by Tata Steel, the Noamundi Iron Ore Mine is a surface mine located in Jharkhand It produced an estimated 825 mtpa of iron ore in The five largest iron ore mines in India Mining Technology

Iron Ore Processing, General Springer

2022年10月19日 — Iron ore mining methods vary by the type of ore being mined Currently, there are four main types of iron ore deposits, depending on the mineralogy and geology of the ore deposits These are magnetite, titanomagnetite, massive hematite, and pisolitic ironstone deposits For taconite iron ores, mining iron ore begins at ground level2013年4月25日 — The process of developing an iron ore mine from exploration data through to informed mining decisions provides an example of a Complex Adaptive System The detailed composition of an ore body (expressed as a “block model” of regularly spaced rectangu lar blocks) has to be estimatPlanning an Iron Ore Mine: From Exploration Data to 6 天之前 — Iron ore mining operations Pilbara region Western Australia The Process of Iron Ore Mining Mining iron ore is a physically and chemically demanding process that takes place in remote locations around the world The process begins with exploration, which can be done through surface or underground methods Once a deposit is discovered, mining Iron Ore Mining – The process of iron ore mining Atlam Resource Recovery and Recycling from Metallurgical Wastes S Ramachandra Rao, in Waste Management Series, 2006 98 Production of Ceramic Tiles from Iron Ore Tailings Current practice of washing iron ore before it is processed for extractive metallurgical operation results in three products, coarse ore lumps with sizes in the range 1080 mm, Iron Ore Processing an overview ScienceDirect Topics

.jpg)

Steel Coal and Iron ore report EY

2024年8月17日 — resources like iron ore, coking/metallurgical coal, steel scrap and power India has adequate iron ore reserves, and utilization of iron ore fines and lowgrade iron ore is a key determinant for the success of the industry India does not have sufficient reserves of coking/metallurgical coal and is dependent on imported coking coal which are2023年1月1日 — The Kemi chromium mine is an openpit mine with a waste rock to ore ratio of 55:1 At Kemi, the ore from the mine contains 11% iron and 255% Cr 2 O 3 After beneficiation, the concentrate contains between 35% Cr 2 O 3 in the coarse fraction (lumps) and 44% of Cr 2 O 3 in the fines The process steps will be explained in the following Chromite ore beneficiation: prospects and challenges2018年7月11日 — The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and low Iron Ore Pelletizing Process: An OverviewIOC's production process begins in the mine with drilling and blasting The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pit "We are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations Our Mining Process Iron Ore Company of Canada

.jpg)

IRON ORE Indian Minerals Yearbook 2019 IBM

2022年5月4日 — from Private Sector Among 35 iron ore mines in Public Sector, 18 iron ore mines each producing more than one million tonnes annually accounted for about 9606% of the total output in Public Sector during 201819 Out of 219 iron ore mines and 8 associated mines in Private Sector, 30 iron ore mines each producing more than2020年2月8日 — The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making With the highgrade ores depleting very fast, the focus is on the beneficiation of lowgrade resources However, most of these ores do not respond well to the conventional Existing and New Processes for Beneficiation of Indian Iron 2023年1月1日 — The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and Iron ore beneficiation: an overview ScienceDirect2023年12月19日 — Using a process that combines coking coal with reduced iron pellets, steelmaking has become one of the world's most vital industries Everything in iron ore mining is big Countries like India are expected to rise, somewhat offsetting the lack of demand from traditional ore buyers worldwideIron Ore Mining Process: From Extraction to Export

Iron Ore Processing, General SpringerLink

2022年10月20日 — Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions It is the link between the mined raw In Goa Foundation vs Union of India Ors, the NGT suspended the ECs granted by the MoEFCC to 72 iron ore mining projects in Goa for violating the EIA Notification, 2006 and the Forest (Conservation) Act, 1980Environmental Clearance Process for Mining Projects in India2017年11月17日 — iron ore reserves [1] P rocessing of low grade iron ore is inevitable as a r esult of increase in production and consumption of high grade ores Though Indian iron ore is rich in iron but it contains high alumina, which is not favorable for efficient operation of blast furnace [2] Indian iron ore mine have been operatedIron Ore Processing eprintsnmlindia2 天之前 — Pyrite mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more Gold Diamond Mining Process in Angola 50TPH Alluvial Diamond Mining Process in Central African 50TPH Diamond Extraction Process Flow Chart 60TPH 15TPH Tailings Lead Barite Pyrite Mining Processing Equipment Flow Chart Cases