Greatest Hammer Crusher For Stone Crushing

Types of Crushers: Choosing the Right One for Each Stage

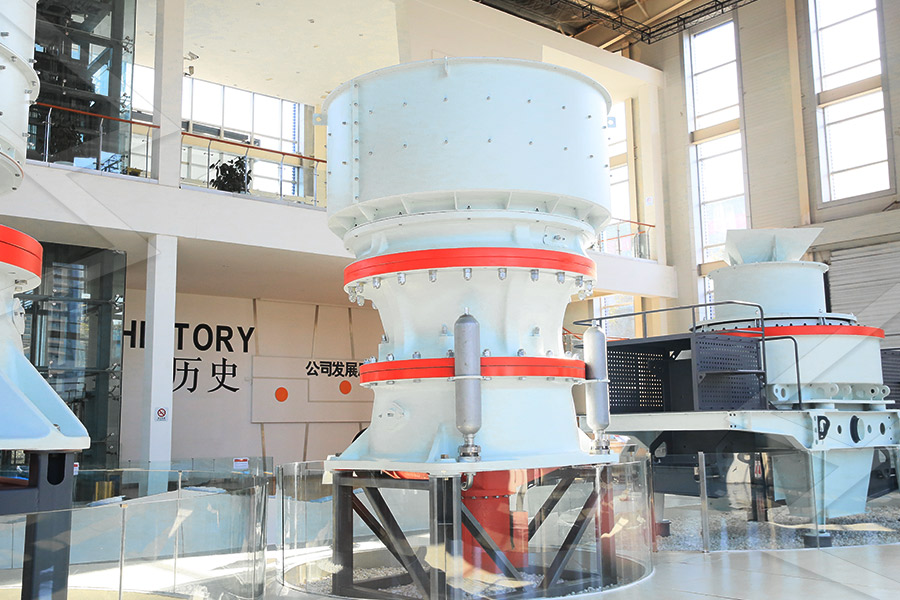

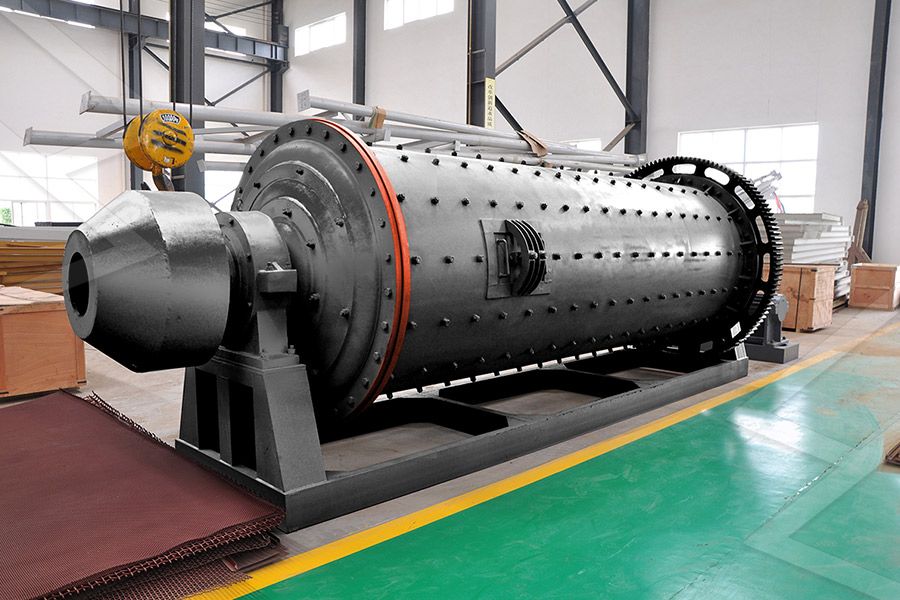

2024年7月17日 — Hammer Crusher Hammer crushers utilize highspeed rotating hammers to impact and crush materials The crushed materials are then propelled at high speed towards the impact plate and grate bar, undergoing multiple impactsA gyratory crusher is one of the most indemand primary crushers for stone What Machines Do Stone 2023年11月20日 — crushing tools By matching the crushing tools to one another, a cubic grain is produced while the proportion of oversize grain is very low The main advantage Comprehensive technical data of crushers for a wide The titan® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials It permits a large feed size and is capable of producing a titan® Crusher thyssenkrupp Polysius Crushing

.jpg)

« DESIGN OF A STONES CRUSHER MACHINE» rufso

2022年4月11日 — Impact stone crusher is used with soft materials, medium to hard stones and medium hard metallic ores The principles used for impact loading is the time for the 2024年7月19日 — The key to obtaining highquality crushed stone is choosing a stone crusher that matches the material characteristics With extensive industry experience and a deep understanding of the How to Crush Stones: A Comprehensive Guide2022年11月21日 — crusher is equipped with a hammer axle extraction device that allows the hammers to be changed completely in only one shift Today, thyssenkrupp TITAN ® doubleshaft hammer crushers ThyssenKrupp2022年5月14日 — Impact crushers are most commonly used in stone quarrying industry for making finegrained stones used in road and building materials The impact crusher as Stone Crushers: A Technical Review on Significant Part of

.jpg)

破碎机产品中心环球破碎机网 ycrusher

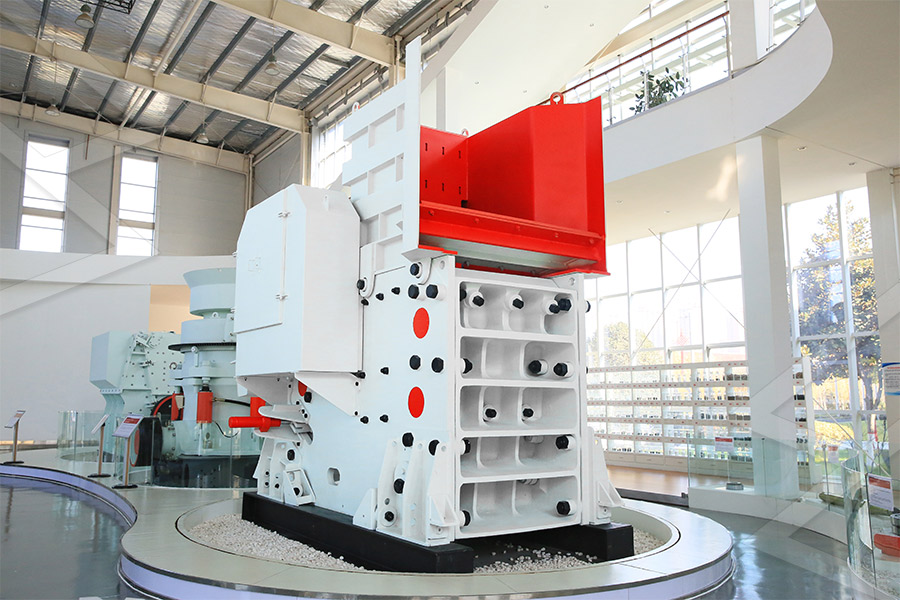

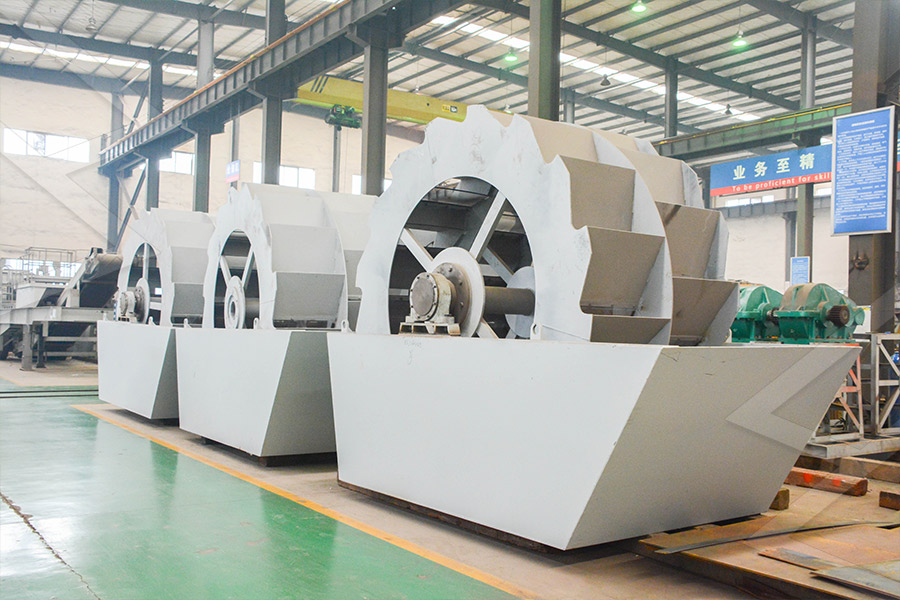

环球破碎机网是中国最大的专业性破碎机网站,收罗全球大量颚式破碎机、圆锥式破碎机、冲击式破碎机、双辊破碎机、塑料破碎机、辊式破碎机、锤式破碎机、复合式破碎机、反 Hammer crusher specification is based on the diameter of the outer end of the rotor and its length dimension 14 Characteristics of hammer crusher 141 Advantages of Hammer Crusher Hammer crusher characterized Hammer crusher INFINITY FOR CEMENT 5 天之前 — They are secondary crushers and suitable for mediumtohard crushing Hammer Crusher This type of stone crusher plant involves a highspeed rotary machine suitable for crushing medium hardness material They have high crushing efficiency and the resulting material has a bit of powdery texture Crushing and screening virgin stone is a great Stone Crusher Machine Efficient Crushing Solutions3 天之前 — The features include great hammerhead work, adoption of new technology casting, with wear and impact resistance This solve the problems of crushing plant dust pollution and gray body leakage 3 Stone Hammer Crusher Structure 4 Stone Hammer Crusher in our Factory 5 Stone hammer crusher ParameterSecondary and Tertiary Crusher Hammer Crusher for Stone,

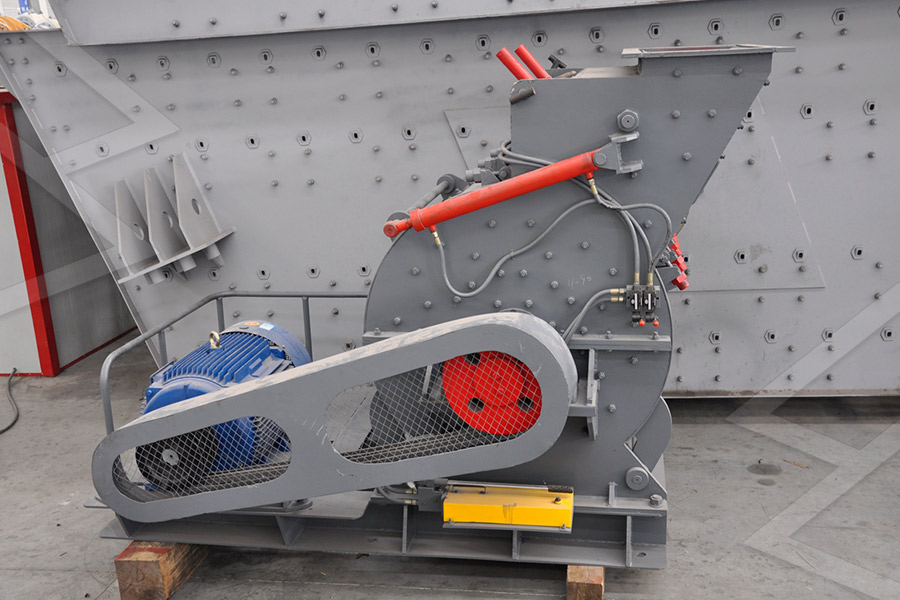

Mining Two Stage Hammer Crusher Machine, Crushing Machine for Stones

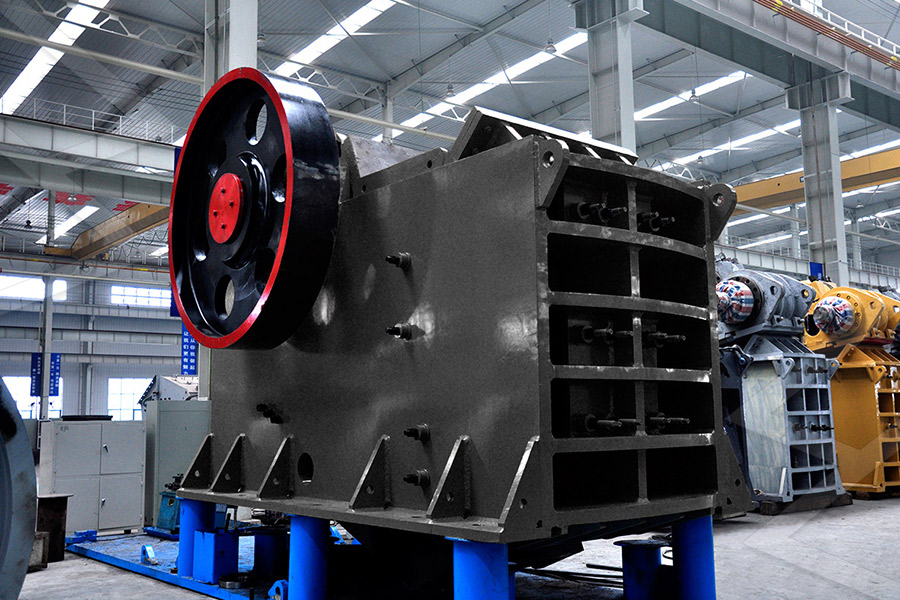

2024年9月7日 — Type: Two Stage Crusher Application: Chemical, Construction, Mineral Industry, Stone Industry Drive: Electric Crushing Style: Extruding Compressive Strength (For Crushing): 100250MPA Crushing Degree: Fine Grinding MachineStone Crusher di Indonesia memainkan peran penting dalam industri Crushing Ada banyak sekali jenis Mesin Stone Crusher yang ada di pasaran Tipe Dia dari kerucut(mm) Menyesuaikan Rentang Pembukaan Debit(mm) Ukuran Umpan Maks(mm) Kapasitas(t/h)Stone Crusher di Indonesia for Sale with Competitive Price2023年11月20日 — crushing tools By matching the crushing tools to one another, a cubic grain is produced while the proportion of oversize grain is very low The main advantage of the tool technology is the larger crushing ratio This means that the grains are drawn in more directly, wear is significantly reduced and sandComprehensive technical data of crushers for a wide 2023年2月21日 — They work by using compressive force to break down the materials Understanding the working principles of jaw crushers is important for ensuring that you choose the right crusher for your specific needs Crushing Process in a Jaw Crusher The crushing process in a jaw crusher begins with the feeding of the material into the The Ultimate Guide to Jaw Crushing Machines: Types

A Guide to Types of Jaw Crushers for Crushing Rocks and

2023年2月15日 — The Blake jaw crusher is the most commonly used jaw crusher in the stone crushing industry It has a high crushing capacity, and it is easy to operate and maintain Construction and Design: The Blake jaw crusher consists of a heavyduty frame that carries a fixed jaw and a movable jaw2024年8月6日 — Hammer crusher is a medium to fine crushing equipment mainly used in industrial Welcome to XKJ GROUP! Provide you with professional ore crushing solutions sales01@xkjgroup Tel 86 Hammer Crusher Introduction2024年3月1日 — 4 Hammer crusher A hammer crusher is a special type of crusher that consists of a rotor with disks on which the hammers are mounted and articulated in the outer area They, therefore, have a design similar to horizontal impact crushers The rotor's high flywheel mass enables the singlestage shredding of feed pieces with edge lengths of up What Machines Do Stone Crushing Plants Need? Fote 2024年2月13日 — 4 Hammer Crusher Hammer crusher adalah jenis stone crusher yang menggunakan hammer untuk menghancurkan batu Hammer crusher terdiri dari rotor yang berputar dengan kecepatan tinggi dan Stoner Crusher: Jenis, Tahapan, dan Komponennya

Hammer Crushers – MEKA

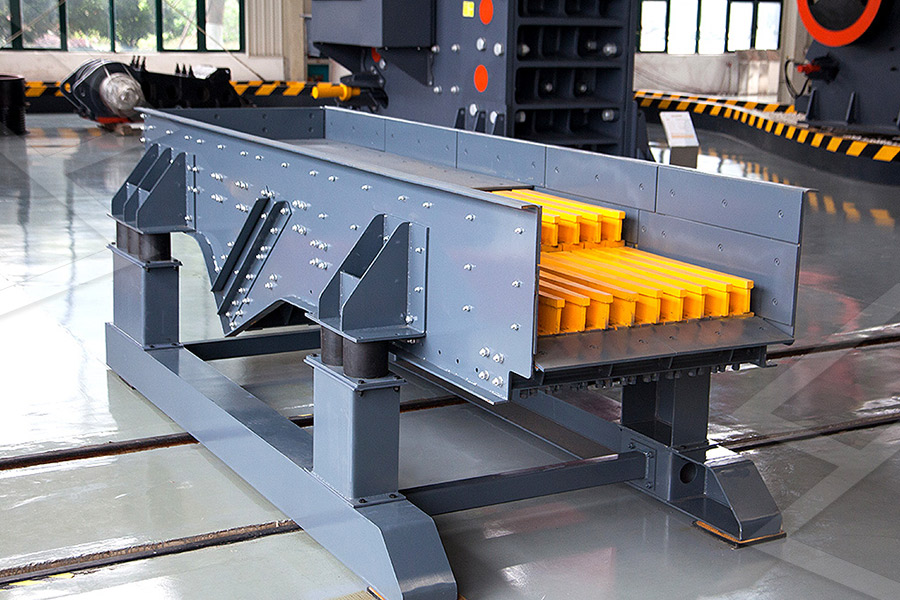

*For material weighing 16 t/m³ or 100 lbs/ft³ Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed Beyond the primary stone crusher and secondary crushers, screeners play a vital role in the stonecrushing process by grading the crushed material by size Screeners, or screening equipment, are integral to this process They work by sorting crushed stones into various size categories using vibrating screens or mechanical separatorsThe Ultimate Guide on How to Crush Stone2024年9月19日 — Stone Crusher, also known as rock crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust and hammer mills, each serving unique crushing purposes Conclusion Understanding the different types and specifications of stone crushers is essential for selecting the most suitable machine for Stone Crusher Crushing Rock Machine2023年12月8日 — As a professional gamer and content creator with over 5,000 hours exploring the Lands Between, I‘ve experimented extensively to discover the most crushing Giant Crusher strength build possible in Elden Ring This comprehensive guide contains my personal tips and analysis on optimizing your Tarnished‘s brute force bonking potential Elden Ring: Ultimate Giant Crusher Strength Build Guide

titan® Crusher thyssenkrupp Polysius Crushing Technologies

The titan® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials It permits a large feed size and is capable of producing a clearly defined finished product size being preselected by the gaps of the discharge grate and therefore able to produce fedd Each type of crusher for each specific crushing stage is explained in greater detail below Primary crushing equipment As the name suggests, this kind of crushing is the first in the process Run of Mine (ROM) materials are brought directly from blasting projects and crushed a primary crusher for the first round of crushingTypes of Crushers: What You Need to Know HUATAO GROUPHammer crusher with feed roller The hammer crusher with feed rollers (FLS) is a special form of construction to avoid complicated, multistage crushing, a hammer has been developed, which does not require preceding primary crushing This crusher reduces rock lumps from 2 m size down 25 mm The crusher uses a single hammer rotor with Everything you need to know about Crushers in Cement 2024年6月28日 — Wide application: Suitable for both dry and wet crushing, for materials with up to 15% moisture Onetime forming: Eliminates the need for primary and secondary crushing, reducing costs by approximately 40% Large feed opening: Handles feed sizes up to 1000 mm, making it ideal for coarse crushing Nonclogging: Designed to ensure What Crusher Should You Choose for Primary Crushing?

.jpg)

Choosing the right crusher for rock, stone, concrete and

Choosing the right crusher for rock, stone, concrete and aggregate is the first step in maximizing the production of your crushing operation Cookie Settings Office Toll Free: 8888529021 44109 Yale Road West, Chilliwack, BC V2R 3Z92024年7月19日 — Features: Impact crushers are suitable for secondary and tertiary crushing of mediumhard, brittle, and lowabrasive stones like limestone and shale They occupy a small footprint and are easy to How to Crush Stones: A Comprehensive GuideChina 50tph 80tph River Stone Granite Concrete Marble Crushing Machine Price Limestone Rock Jaw Hammer Crusher Line Supplier US$4,80000 12,00000 / Set 1 Set (MOQ)Jaw Crusher Manufacturer, Hammer Cruser, 2024年7月17日 — Primary crushing is the first stage of the stone crushing process At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers Jaw CrusherTypes of Crushers: Choosing the Right One for Each Stage

Limestone Crushing And SandMaking Plant Eastman Rock Crusher

2024年1月11日 — 3 Hammer Crusher The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a 2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of The Complete Guide to Primary Crushing, Secondary CrushingPortable Hammermill Crushers offer fast onsite set up and high production for crushing aggregates, minerals and ores with approximate throughput of 1 to 2 tons (900 to 1,800kg)/hourMaximum feed size is 2in (51mm) with final output size to No80 (02mm) fineness They perform well for highvolume laboratory, pilot plant and small production Hammermill Crushers Gilson Co GlobalGilson2024年9月25日 — 101000tph large capacity high efficient stone crusher plants starting from $6000 for sale Get quick return with Shunzhi equipment!Stone Crusher Plant For Sale Shunzhi Mining Machinery

Rock Crushers Pulverizers Williams Crusher

Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper In some applications, primary crushing alone can suffice However, primary crushing is often followed by secondary crushing and tertiary crushing2023年2月15日 — Crushing process two uses a hammer crusher Crushing process three uses a singlecylinder cone crusher Crushing process: Asphalt concrete has three crushing processes The selection of crushers should be based on the customer’s needs and actual conditions Crushing process one The jaw crusher has a large crushing ratio, small Which Crusher Is Suitable for Your Hard Rock? Fote 3 天之前 — Key Components: Rotor: Rotates at high speed inside the crushing chamber; Hammer: Fixed to the rotor, hammers impact the material to be crushed; Grate Bars: Adjustable openings at the bottom of the crusher where crushed material exits; Housing: Encloses the rotor assembly and the crushing chamber; Feed Inlet: Allows material to be Heavy Hammer Crusher TAYMACHINERYHammermill Crushers are known to generate material finer than 3/16" (4mm), which in some applications may be undesirable However, if there is a market for finer material, or if it is acceptable within the desired product size, Hammermills can achieve reduction ratios that may otherwise require multiple crushersHammermill Crushers McLanahan

Rock Crushers, for Tractors and Skid Steers For Sale FAE

An FAE stone crusher from the STCL series is just what you need, with the ability to work up to 15 cm deep The FAE STC/SSL stone crushers transform your skid steer into an effective machine for multiple applications: crushing stones, building and maintaining hiking trails, bike paths and horse trails, dirt and gravel road maintenance2021年3月25日 — The main features of a Gyratory Crusher include a tall crushing chamber lined with replaceable manganese wear plates, a main shaft with head and mantle, and a spider to anchor the top of the main What Type of Crusher Is Best for Primary 2024年6月7日 — Established in 1965, we are a pioneering enterprise in China's machinery industry, specializing in stone crushing equipment With a comprehensive range including jaw crushers, cone crushers, impact crushers, hammer crushers, mobile crushers, and more, we lead the industry with innovative solutions and superior product quality Our About us: China Stone Crusher Manufacturer and SupplierWide opening jaw crusher: It has a 18 by 26inch jaw feed opening for crushing sizable concrete chunks Dual conveyor crushing plant: The Senya 6 has a two conveyor system to process debris and aggregate faster Metals removal feature: This concrete crusher’s magnetic conveyor removes rebar, wire, and metal components for youSenya 6 Portable Concrete Crusher Senya Crushers

.jpg)

Limestone Crusher: An Edge Tool for Making Crushed

2024年7月15日 — 4 Temporary limestone crushing needs: mobile crusher If you have temporary limestone crushing needs, or your rock crushing plant is remote, mobile crusher is an ideal choice for limestone rock In addition, you can match the mobile crusher with different stone crushers according to your needs 5 Limestone sand: sand making machine2024年3月5日 — Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader Hamm HC 250 Roller Compactors New Vibration Crusher Offer SinglePass Crushing Compacting gyratory crushers are suspended Impact crushers, sometimes called “hammer crushers,” use mass and velocity to break Crusher Aggregate Equipment For Sale MachineryTrader2024年8月29日 — Using a gravel crusher is a great way to save time and effort compared to manually crushing gravel yourself #5 A gravel crusher can be used for many projects, making it a highly versatile piece of equipment #6 A gravel crusher can help you get the gravel you need, even in remote locations that may not have gravel suppliers nearby #7What Is A Gravel Crusher How Does It Work? vykin2024年9月20日 — They are suitable for crushing various types of stones, including hard and abrasive materials Cone crushers offer excellent particle shape control and can be used in both secondary and tertiary crushing applications Hammer Crusher Hammer crushers, also known as hammer mills, are used for crushing brittle and mediumhard materialsA Comprehensive Guide to Stone Crusher in Indonesia

Stone crusher, used stone crusher for sale Machinerylinefo

Stone crushers 100 offers Price from €8,300 New and used Trusted sellers Currently in stock Quality construction equipment for sale at Machineryline Machineryline » Mining equipment » Crushing equipment Agromeks 150cm Stone Crusher enterrador de piedra Kamnedrobilka كسارة الح price on requestHammer crusher specification is based on the diameter of the outer end of the rotor and its length dimension 14 Characteristics of hammer crusher 141 Advantages of Hammer Crusher Hammer crusher characterized Hammer crusher INFINITY FOR CEMENT 5 天之前 — They are secondary crushers and suitable for mediumtohard crushing Hammer Crusher This type of stone crusher plant involves a highspeed rotary machine suitable for crushing medium hardness material They have high crushing efficiency and the resulting material has a bit of powdery texture Crushing and screening virgin stone is a great Stone Crusher Machine Efficient Crushing Solutions3 天之前 — The features include great hammerhead work, adoption of new technology casting, with wear and impact resistance This solve the problems of crushing plant dust pollution and gray body leakage 3 Stone Hammer Crusher Structure 4 Stone Hammer Crusher in our Factory 5 Stone hammer crusher ParameterSecondary and Tertiary Crusher Hammer Crusher for Stone,

.jpg)

Mining Two Stage Hammer Crusher Machine, Crushing Machine for Stones

2024年9月7日 — Type: Two Stage Crusher Application: Chemical, Construction, Mineral Industry, Stone Industry Drive: Electric Crushing Style: Extruding Compressive Strength (For Crushing): 100250MPA Crushing Degree: Fine Grinding MachineStone Crusher di Indonesia memainkan peran penting dalam industri Crushing Ada banyak sekali jenis Mesin Stone Crusher yang ada di pasaran Tipe Dia dari kerucut(mm) Menyesuaikan Rentang Pembukaan Debit(mm) Ukuran Umpan Maks(mm) Kapasitas(t/h)Stone Crusher di Indonesia for Sale with Competitive Price2023年11月20日 — crushing tools By matching the crushing tools to one another, a cubic grain is produced while the proportion of oversize grain is very low The main advantage of the tool technology is the larger crushing ratio This means that the grains are drawn in more directly, wear is significantly reduced and sandComprehensive technical data of crushers for a wide 2023年2月21日 — They work by using compressive force to break down the materials Understanding the working principles of jaw crushers is important for ensuring that you choose the right crusher for your specific needs Crushing Process in a Jaw Crusher The crushing process in a jaw crusher begins with the feeding of the material into the The Ultimate Guide to Jaw Crushing Machines: Types

A Guide to Types of Jaw Crushers for Crushing Rocks and

2023年2月15日 — The Blake jaw crusher is the most commonly used jaw crusher in the stone crushing industry It has a high crushing capacity, and it is easy to operate and maintain Construction and Design: The Blake jaw crusher consists of a heavyduty frame that carries a fixed jaw and a movable jaw2024年8月6日 — Hammer crusher is a medium to fine crushing equipment mainly used in industrial Welcome to XKJ GROUP! Provide you with professional ore crushing solutions sales01@xkjgroup Tel 86 Hammer Crusher Introduction2024年3月1日 — 4 Hammer crusher A hammer crusher is a special type of crusher that consists of a rotor with disks on which the hammers are mounted and articulated in the outer area They, therefore, have a design similar to horizontal impact crushers The rotor's high flywheel mass enables the singlestage shredding of feed pieces with edge lengths of up What Machines Do Stone Crushing Plants Need? Fote