Acid Grade Flourspar Processing Plant

Fluorspar USGS Publications Warehouse

2023年1月9日 — An estimated 40,000 tons of fluorosilicic acid (FSA), equivalent to about 65,000 tons of fluorspar grading 100% CaF2, was recovered from three phosphoric acid The main grades of fluorspar available are: crude ore 2530% metallurgical grade 7582% ceramic grade 9496% acid grade 97% crystalline grade 99% The most demanded is the acid grade, used as raw material to HF production EurofluorXinhai Fluorite (Fluorspar) Flotation Process can help you to obtain high grade fluorite concentrate The dressing plant has advantages of stable equipment operation, mature technology and low cost Welcome to visit fluorspar processing, fluorspar processing 2021年2月4日 — Domestically, production of HF in Louisiana and Texas was by far the leading use for acidgrade fluorspar Hydrofluoric acid is the primary feedstock for the Fluorspar USGS Publications Warehouse

Nokeng: Mining fluorspar hills African Mining

2019年9月30日 — Nokeng’s concentrator will produce about 180 000t of acid grade fluorspar (97% pure fluorspar) and 30 000t of metallurgical grade fluorspar annually from runofmine fluorspar ore production of 630 000t 2024年6月27日 — Fluorspar has a wide range of industrial applications, including the production of hydrofluoric acid, aluminum fluoride, and fluorocarbons In this ultimate guide to fluorspar processing, we will The Ultimate Guide to Fluorspar Processing2020年5月21日 — grades — acid, metallurgical and ceramic All UK output is acidgrade fluorspar (>97%, CaF2), used principally in the production of hydrofluoric acid (HF), the Mineral Planning Factsheet Fluorspar Mining The result is Vergenoeg Mining Company (VMC Fluorspar): the main (frequently the only) South African producer of this mineral, and one of the largest in the World, with a Vergenoeg Mining Company

96% CaF 2) is used" h="ID=SERP,54052">Optimization of Highgrade Fluorspar Recovery from Rare

2022年9月9日 — Highpurity fluorspar (> 96% CaF 2) is used to produce hydrofluoric acid (HF), a feedstock for various chemical processes, including the production of 2023年7月12日 — US: Ares Strategic Mining, the only company with a permitted Fluorspar mine in the US, has announced plans to build a $19 million firstofitskind processing facility in Delta, Utah The 22,000 Utah to Unveil North America's First Domestic 2023年1月29日 — Our #Flourspar Processing #Plant at mine site, has annual processing capacity of 100,000 tonnes raw fluorspar infeed Germany and other countriesOur mining license covers around 150 hectares Gobi Shoo LLC FLUORSPAR Mining And Processing Private 2023年1月9日 — from the US Department of Agriculture which it expected would be used to fund completion of a metallurgicalgrade fluorsparprocessing plant, rail spur, and tailings dam An estimated 40,000 tons of fluorosilicic acid (FSA), equivalent to about 65,000 tons of fluorspar grading 100% CaF 2, was recovered from three phosphoric acid plants Fluorspar USGS Publications Warehouse

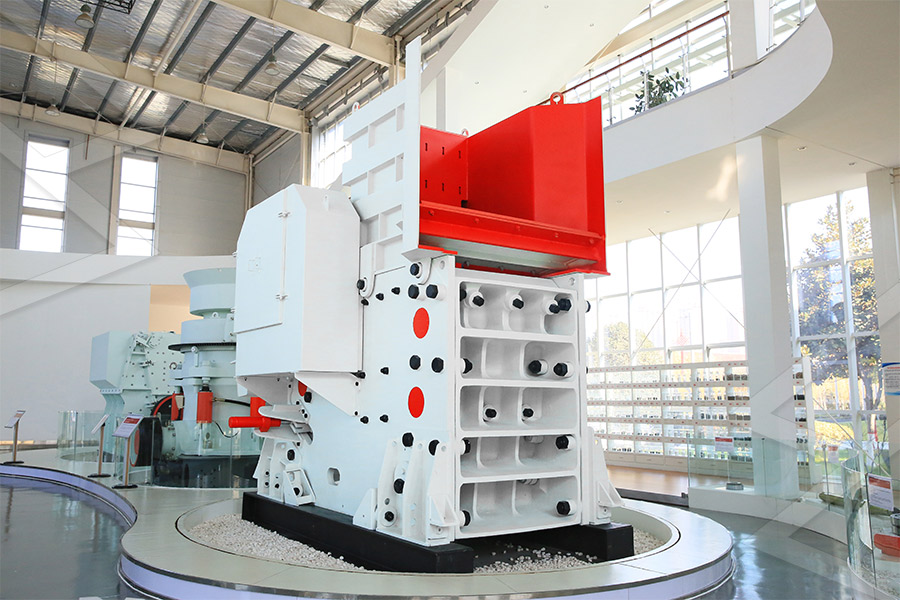

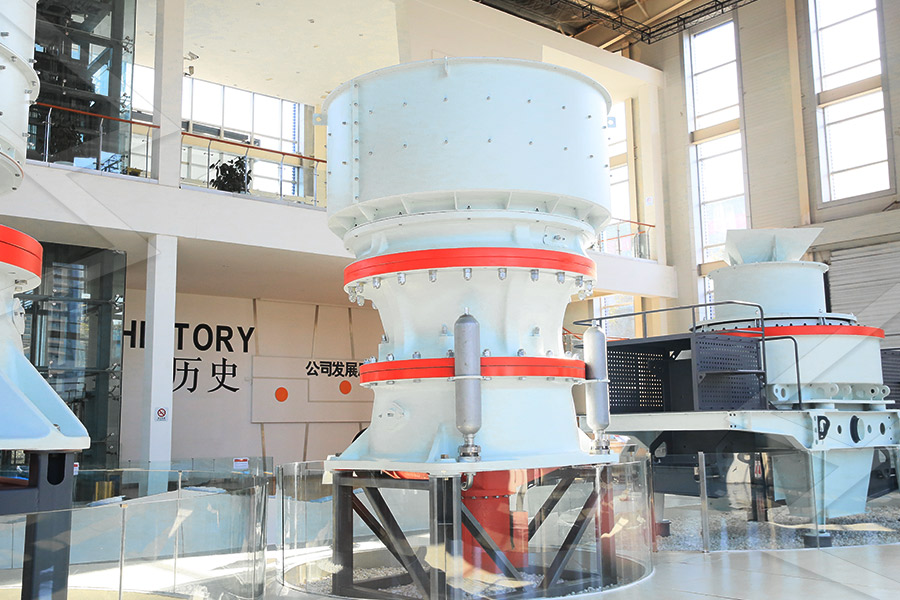

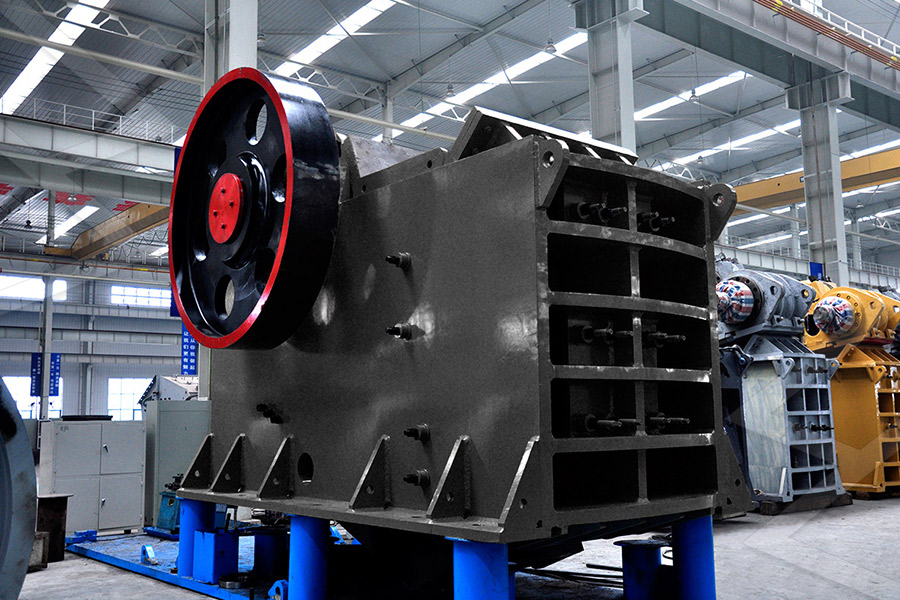

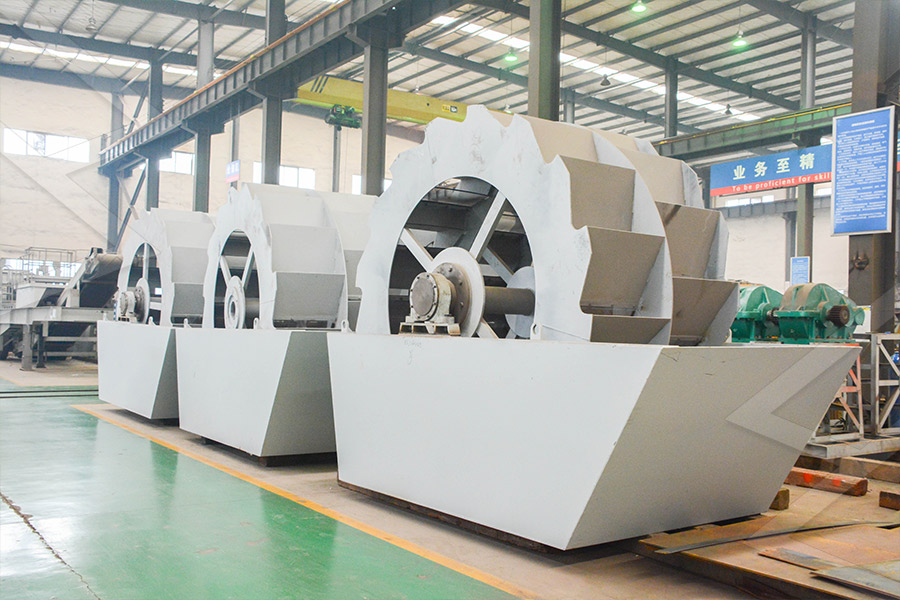

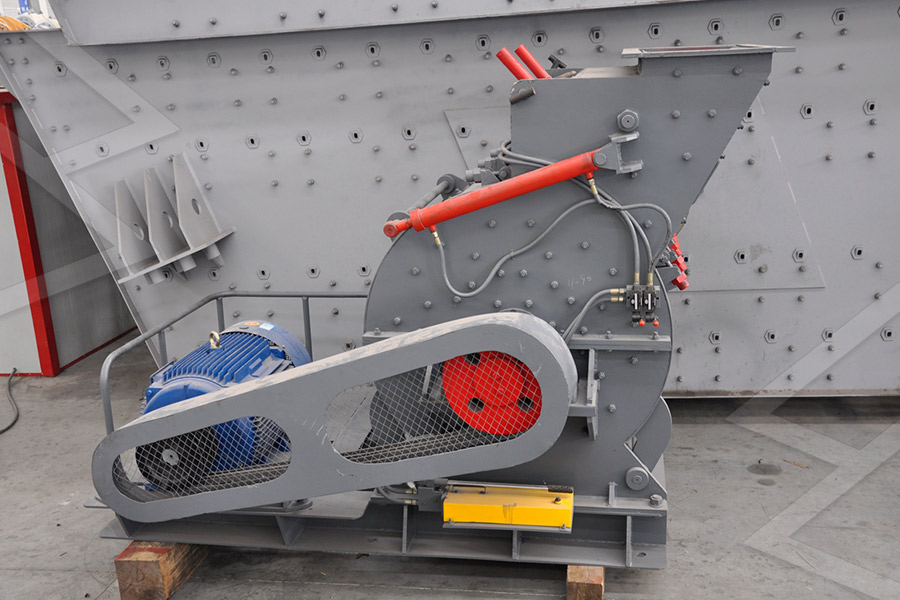

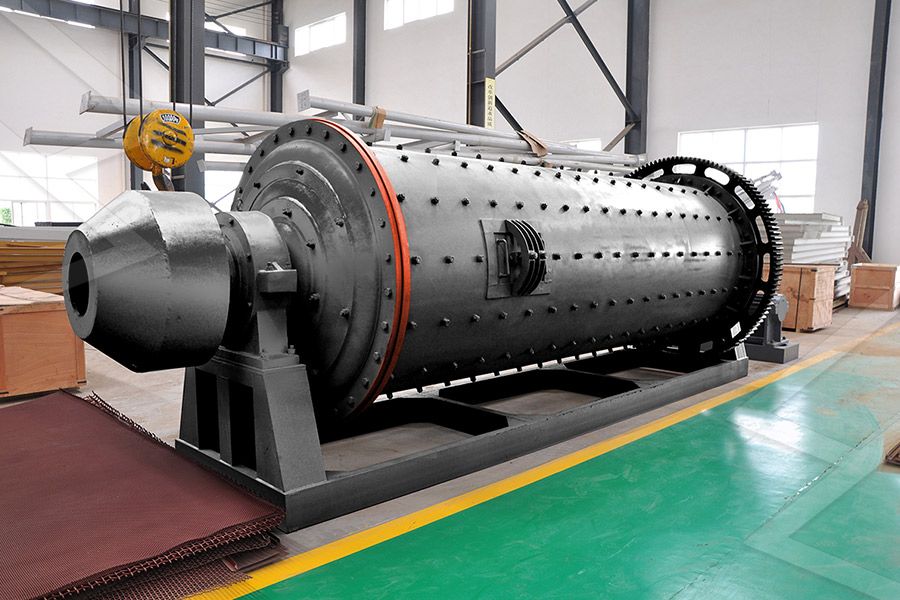

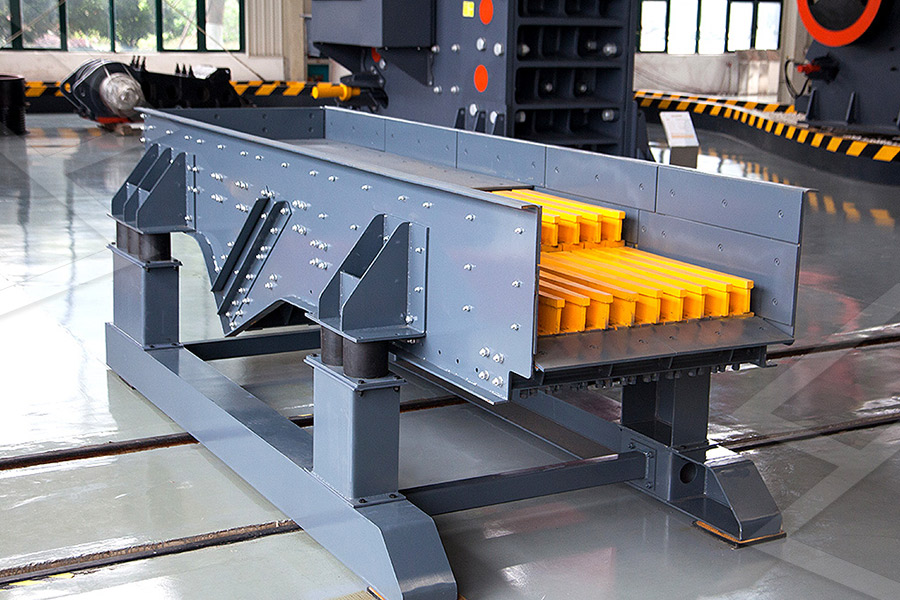

Four Common Types Of Fluorspar Mineral Processing Methods

2024年9月24日 — Fluorspar mineral processing is a complex field that requires a variety of methods to extract and refine this valuable mineral One common type is gravity separation, which involves separating fluorspar from other minerals based on differences in densityThis method is costeffective and environmentally friendly, making it a popular choice in Our Process Kenya Fluorspar operated across seven separate mining sites located within a radius of 10km from the processing plant, from which ore was mined depending on the grade and quality of the blend Initially only metallurgical grade fluorspar was produced from the mined ore, but a 100,000ton per annum acid grade fluorspar Our Process Kenya Fluorspar2023年2月15日 — Fluorite ore processing plant 1 Africa 100TPD fluorite ore processing plant In a fluorite beneficiation plant in Africa, fluorite and quartz are the main minerals, and there is a small amount of pyrite, sericite, chlorite, calcite, barite, clay minerals and various sulfides The disseminated size of fluorite does not show extragranular 4 Steps to Process Complex Lowgrade Fluorite OreFluosilicic acid (FSA) is a potential source of fluorine raw material instead of using fluorspar (fluorite ore) for the production of anhydrous hydrofluoric acid (AHF) and its further downstream Typical process block diagram for the manufacture of hydrofluoric acid

Nokeng: Mining fluorspar hills African Mining Online

2019年9月30日 — Nokeng’s concentrator will produce about 180 000t of acid grade fluorspar (97% pure fluorspar) and 30 000t of metallurgical grade fluorspar annually from runofmine fluorspar ore production of 630 000t Openpit mining and modern plant efficiency is expected to put Nokeng in the bottom cost quartile internationally2018年6月14日 — Fluorite is a nonmetallic mineral, containing 511 percent calcium and 489 percent fluorine Industry practice has established three grades of fluorspar: acid grade (containing more than 97 percent calcium fluoride), ceramic grade (85 to 95 percent calcium fluoride) and metallurgical grade (normally 60 to 85 percent calcium fluoride)Mineral Resource of the Month: Fluorspar EARTH MagazineVergenoeg Mining (VMC Fluorspar) Fluorspar production in South Africa Vergenoeg combines an excellent local team, a unique mineral deposit and Minersa’s most extensive experience in the fluorspar world The result is Vergenoeg Mining Company (VMC Fluorspar): the main (frequently the only) South African producer of this mineral, and one Grupo MinersaSeaforth Mineral Ore with corporate headquarters in the Cleveland area, processes and distributes fluorspar from its centrally located plant in East Liverpool, Ohio Best Fluorspar Buy We take pride in being able to Fluorspar Supplier Seaforth Mineral

Okorusu, Namibia ResearchGate

2023年12月29日 — of the processing plant for beneficiation of graphite from a neighboring mine Figure 1 acidgrade fluorspar product with 972 percent and a mine life of 10 years It is deemed necessary2024年4月9日 — 氟酸(也称氟化氢)是一种无色液体,具有刺激性气味。它是一种强酸,具有 highly corrosive property(高腐蚀性)和 highly toxic property(高毒性)。它在常温下可以与许多物质快速反应。氟酸化工百科 ChemBKA fluorite dressing plant in Hebei, the fluorite with low ore grade, high oxidation, fine granularity distribution and small hardness, the original production process was concentrate regrinding and seven times cleaning, concentrate grade of 88%, recovery rate of 7556%fluorspar processing, fluorspar processing plants, fluorspar Fluorspar, the name used for fluorite when it is sold as a bulk material or in processed form, is sold in three different grades (acid, ceramic, and metallurgical) Acid Grade Fluorspar Acid grade fluorspar is a highpurity material used by the chemical industry It contains over 97% CaF 2 Most of the fluorspar consumed in the United States Fluorite and Fluorspar: Mineral uses and properties

Manufacturing process for Hydrofluoric acid VALCO GROUP

2 天之前 — In general the process involves the following stages: fluorspar drying, reaction of fluorspar with sulfuric acid, hydrofluoric acid purification and scrubbing To make high grade HF (9998 percent pure), the crude liquid HF is reboiled and distilled Figure 1 Simplified process flow diagram for a fluorspar plantAcid Grade Fluorspar Fluorite (also called fluorspar) is a halide mineral composed of calcium fluoride, CaF2 It is an isometric mineral with a cubic habit, though octahedral and more complex isometric forms are not uncommon The purest grades of fluorite are a source of fluoride for hydrofluoric acid manufacture, which is the intermediate Acid Grade Fluorspar – J P CHEMICALSMPD Fluorspar Fluorspar Mining in Asturias, Spain With a production capacity of about 140,000 tpy, our mines in Asturias turn Minersa into the largest fluorspar producer in Europe Our Ribadesella (Mina Ana) team accumulates much of Minersa’s knowledge in fluorsparIts processing plant with inhouse developed process control technology, Grupo MinersaOur #Flourspar Processing #Plant at mine site, has annual processing capacity of 100,000 tonnes raw fluorspar infeed Germany and other countriesOur mining license covers around 150 hectares area and #FPP produces acid grade (FF98) and #metallurgical #grade (FK 8590) Fluorspar concentrates //gobishoomining As Industry Leader In Gobi Shoo LLC FLUORSPAR Mining And Processing Private

Fluorspar is Currently Witnessing High Demand as Increasing

2021年1月27日 — Hydrofluoric acid also is used in manufacturing computer chips and highoctane gasoline, stainless steel pickling and uranium fuel processing Acid or ceramicgrade fluorspar also may be used to 2018年1月11日 — Acidgrade fluorspar, containing 97 percent or greater of calcium fluoride, is the primary source of fluorine in consumer products and manufacturing processes Metallurgical grade fluorspar, containing less Mineral Resource of the Month: Fluorspar2023年8月24日 — Fluorochemicals have a wide range of applications in industry, but accessing these relies on the energy intensive conversion of acidgrade fluorspar (CaF2) to toxic hydrogen fluoride (HF) gas Access to fluorochemicals directly from fluorspar2022年1月20日 — Calcium fluoride that is consumed by the chemical industry requires the highest grade (acid grade) with a minimum of 97% CaF 2 content Ceramic grade (85–95% CaF 2 ) is used in the manufacture of glasses, enamels and cooking utensils, whereas a metallurgical grade (60–85% CaF 2 ) is traditionally applied in welding fluxes and Optimizing the recovery process of ceramic grade calcium

Summary of Fluorite Ore Flotation Process JXSC Machine

2019年4月24日 — How is Fluorite Extracted? Summary of Fluorite Ore Flotation Process Taking deep research on the features, extraction methods, and fluorite mining machines have a significant positive effect on running the fluorite processing plant successfullyThe Fluorspar Market is expected to reach 770 million tons in 2024 and grow at a CAGR of 276% to reach 882 million tons by 2029 China Kings Resources Group Co Ltd, Mongolrostsvetmet LLC, Minersa Group, Masan HighTech Materials Corporation and Koura are the major companies operating in this marketFluorspar Market Share, Size Industry Trends Mordor We are focused on surface and underground mining and processing operations in Dundgobi province, where all necessary social infrastructures are in place, including transportation Our #Flourspar Processing #Plant at mine site, has annual processing capacity of 100,000 tonnes raw fluorspar infeedGobi shoo llc fluorspar mining and processing private entity2021年5月2日 — Contact with hot concentrated sulfuric acid: Possibility ofproduction ofhydrofluoric acid (Hydrogen fluoride) Amorphous silica: Violent reaction with: Fluoride, oxygen difluoride, chlorine trifluoride Calcium carbonate: Alum, ammonium salts, mercury and hydrogen, fluorine, magnesium, acids NOTE: This list ofproducts is not exhaustiveFLUORSPAR (Acid Grade) Material Safety Data Sheet

9 FLUORSPAR SCRREEN

2023年1月31日 — analysed At mine stage, fluorspar is assessed in the form of fluorspar acid grade “AG” (assuming 97% CaF 2 contained, CN8 code ) and metallurgical grade “MG” content while for processing stage the quantities are expressed in fluorine (F) content The EU wasa net importer of fluorspar at mine stage in 20122016 (AG and MG 2019年8月5日 — SepFluor's mine and plant were officially opened on August 1 DIGITAL MAGAZINE; About; CONTACT US; The mine's concentrator will produce around 180,000t of acidgrade fluorspar (97% pure fluorspar) and 30,000t of metallurgicalgrade fluorspar annually from runofmine fluorspar ore production of 630,000tNokeng fluorspar mine comes online Mining Magazine2024年2月19日 — The production of this electrolyte salt relies heavily on hydrofluoric acid derived from fluorspar • Anode purification – Hydrofluoric acid also plays a crucial role in removing impurities like silica from Fluorspar: the forgotten battery mineral Metal 2020年10月14日 — Ares Strategic Mining (TSXV: ARS) announced that it has received approval to commence mining operations and an environmental permit for its Lost Sheep fluorspar project in UtahAres Strategic to start operations at only

acid grade flourspar processing plant chateaudecarolleco

Flowsheets Flowcharts Archives Fluorspar Beneficiation Process Plant The Fluorspar Beneficiation Problem Acid grade fluorspar which is in great demand by the chemical and aluminum industries, must contain at least 975% CaF2 with 2020年5月5日 — Our Flourspar Processing Plant at mine site, has annual processing capacity of 100,000 tonnes raw fluorspar infeed Germany and other countriesOur mining license covers around 150 hectares Welcome To GOBISHOO CO,Ltd FLUORSPAR MINING ORE AND PROCESSING 2018年12月13日 — • High grade of ~40% CaF 2 (Plattekop) • Cheap to mine: open pit, virtually no overburden, low cost of production, latest technology • Located close to major services • 19year LOM • first production by Q1 2019 • 180ktpa acid grade fluorspar • 30ktpa metallurgical grade fluorspar • 630 000tpa average ROM feed rateNOKENG FLUORSPAR MINE2019年7月12日 — Over its 19year lifespan operating at a 630,000tpa ROM production rate, the operation will deliver 180,000 tpa of acid grade fluorspar and 30,000tpa of metallurgical grade fluorspar The ore grade at an average of 27% calcium fluoride (CaF₂), is considered high Nokeng is an open pit operation and the two ores bodies are easily accessibleNokeng Fluorspar Mine on track to realise full potential

fluorspar:trade technology project information

2020年12月10日 — The most demanded is the acid grade, used as raw material to produce hydrofluoric acid, its worldwide production capacity being more than three million metric tonnes Project Scope cash flow flotation processing plant operating at a rate of 800,000 TPY 2018; Technology of Fluorspar Beneficiation Plant Acid grade Fluorspar JIN CHANG SOENG MINING CO,LTD, which was established in 2011, has two fluorspar flotation plants, one briquetting plant and one fluorspar drying powder plant Among them, one flotation plant with a raw ore processing capacity of 1000 tons per day, a briquetting plant with a capacity of 80 tons per day, and a drying plant with a capacity of 80 Company Profile Jin Chang Soeing Mining Co, Ltd2023年7月25日 — The establishment of technological approaches for the defluorination of waste fluoropolymers and recovery of eliminated F– may contribute to the development of fluorine recycling routes In this study, we investigated the effects of alkalinity, phase transfer catalyst (PTC) concentration, reaction temperature, and solvent types on the Fluorine recovery through alkaline defluorination of Acid grade fluorspar (acidspar) – a highpurity material used by the chemical industry It contains over 97% CaF 2 Most of the fluorspar consumed in the USA is acid grade even if it is used in lower grade applications Acidspar is used mainly in the chemical industry to manufacture hydrofluoric acid The hydrofluoric acid is then used to About Fluorspar – Sepfluor

Utah to Unveil North America's First Domestic

2023年7月12日 — US: Ares Strategic Mining, the only company with a permitted Fluorspar mine in the US, has announced plans to build a $19 million firstofitskind processing facility in Delta, Utah The 22,000 2023年1月29日 — Our #Flourspar Processing #Plant at mine site, has annual processing capacity of 100,000 tonnes raw fluorspar infeed Germany and other countriesOur mining license covers around 150 hectares Gobi Shoo LLC FLUORSPAR Mining And Processing Private 2023年1月9日 — from the US Department of Agriculture which it expected would be used to fund completion of a metallurgicalgrade fluorsparprocessing plant, rail spur, and tailings dam An estimated 40,000 tons of fluorosilicic acid (FSA), equivalent to about 65,000 tons of fluorspar grading 100% CaF 2, was recovered from three phosphoric acid plants Fluorspar USGS Publications Warehouse2024年9月24日 — Fluorspar mineral processing is a complex field that requires a variety of methods to extract and refine this valuable mineral One common type is gravity separation, which involves separating fluorspar from other minerals based on differences in densityThis method is costeffective and environmentally friendly, making it a popular choice in Four Common Types Of Fluorspar Mineral Processing Methods

Our Process Kenya Fluorspar

Our Process Kenya Fluorspar operated across seven separate mining sites located within a radius of 10km from the processing plant, from which ore was mined depending on the grade and quality of the blend Initially only metallurgical grade fluorspar was produced from the mined ore, but a 100,000ton per annum acid grade fluorspar 2023年2月15日 — Fluorite ore processing plant 1 Africa 100TPD fluorite ore processing plant In a fluorite beneficiation plant in Africa, fluorite and quartz are the main minerals, and there is a small amount of pyrite, sericite, chlorite, calcite, barite, clay minerals and various sulfides The disseminated size of fluorite does not show extragranular 4 Steps to Process Complex Lowgrade Fluorite OreFluosilicic acid (FSA) is a potential source of fluorine raw material instead of using fluorspar (fluorite ore) for the production of anhydrous hydrofluoric acid (AHF) and its further downstream Typical process block diagram for the manufacture of hydrofluoric acid 2019年9月30日 — Nokeng’s concentrator will produce about 180 000t of acid grade fluorspar (97% pure fluorspar) and 30 000t of metallurgical grade fluorspar annually from runofmine fluorspar ore production of 630 000t Openpit mining and modern plant efficiency is expected to put Nokeng in the bottom cost quartile internationallyNokeng: Mining fluorspar hills African Mining Online

Mineral Resource of the Month: Fluorspar EARTH Magazine

2018年6月14日 — Fluorite is a nonmetallic mineral, containing 511 percent calcium and 489 percent fluorine Industry practice has established three grades of fluorspar: acid grade (containing more than 97 percent calcium fluoride), ceramic grade (85 to 95 percent calcium fluoride) and metallurgical grade (normally 60 to 85 percent calcium fluoride)Vergenoeg Mining (VMC Fluorspar) Fluorspar production in South Africa Vergenoeg combines an excellent local team, a unique mineral deposit and Minersa’s most extensive experience in the fluorspar world The result is Vergenoeg Mining Company (VMC Fluorspar): the main (frequently the only) South African producer of this mineral, and one Grupo Minersa